There are many ways an item can be decorated, and you will find these terms referred to in any correspondence with us. Here we talk about some of our more popular decorative methods.

We believe it is important you understand each option along with the pro and cons of any decorative process, so this section provides some background information for you when choosing what will work best for you.

SUBLIMATION

Sublimation is the process of transferring dye to a fabric using heat. The images and graphics are printed on special paper placed on the garment and heat is applied, allowing the ink to become part of the fabric. As the dye becomes embedded in the actual fibres, it results in a permanent print.

In the print-on-demand world, it’s the go-to printing method for creating all-over print products.

PRO'S

- Fast, professional & hassle-free solution for stunning, full-colour high resolution result.

- Will not crack, fade or peel.

- Unlimited colours and size options available.

- Only the one set up cost irrespective of the number of colours in the design.

ADDITIONAL BENEFITS THROUGH TMA SUPPLY

- Our design team redraw any poor artwork supplied to ensure crisp, clean decoration result.

- No minimum order & a solution for very small, ongoing requirements.

- On-premise equipment with orders supplied within days where required.

- Can also be applied to headwear and suitable across seamlines.

CON'S

- Can be a little more costly (depending on design & application).

- Primarily limited to polyester based materials.

POWER PRINT (TRANSFERS)

Powerprint is an effective laser print transfer medium that transfers images from a laser printer to fabrics, wood, paper, ceramic, cardboard, canvas & metal surfaces. The transfers once printed are then applied to items using a heat press to apply both heat and pressure to imprint designs onto item.

PRO'S

- Fast, professional & hassle-free solution for stunning, full-colour high resolution result.

- Will not crack, fade or peel.

- Unlimited colours and size options available.

- Only the one set up cost irrespective of the number of colours in the design.

ADDITIONAL BENEFITS THROUGH TMA SUPPLY

- Our design team redraw any poor artwork supplied to ensure crisp, clean decoration result.

- No minimum order & a solution for very small, ongoing requirements.

- On-premise equipment with orders supplied within days where required.

- Can also be applied to headwear and suitable across seamlines.

CON'S

- Cannot be ironed & can breakdown to some extent if item not washed correctly or poorly treated.

- More costly than sublimation when individual names &/or numbers are required.

- Can be more costly than screen printing when larger volume quantities & larger images.

EMBROIDERY

Embroidery is the craft of decorating fabric or other materials using a needle to apply thread or yarn. Modern commercial embroidery machines can sew at speeds greater than 900 stitches per minute and maintain perfect quality. Embroidery is available in a wide variety of thread or yarn colours.

PRO'S

- Withstands the rigours of daily wear and constant washing.

- No minimum order requirements or colours that can be used.

- Good option for individual personalisation when adding smaller names, initials & numbers.

- Single set up cost irrespective of the image complexity & number of colours in the design.

ADDITIONAL BENEFITS THROUGH TMA SUPPLY

- Once digitised, no additional set up costs for repeat orders. This includes any small future design tweaks required.

- Orders can be supplied within days where required.

- Our team has over 20 years of experience & use the most current embroidery machines & quality thread.

CON'S

- Small detail, especially small text is often not easily recognised when embroidered.

- Limited colours and size options available.

- Can be more costly for larger image sizes with high stitch counts.

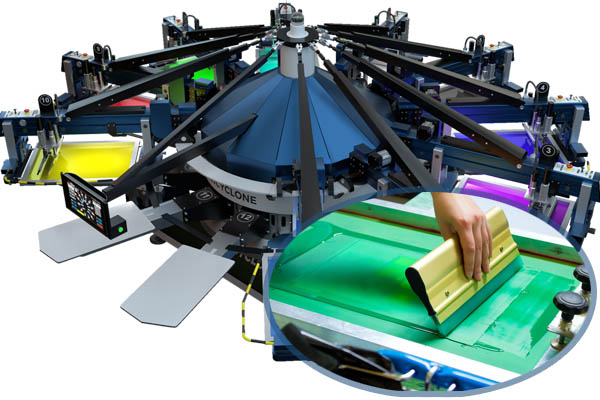

SCREEN PRINTING

Screen Printing, also referred to as Silk Screening, is a popular printing method that presses ink through a mesh screen in order to create a printed design. With screen printing, the design is put as a layer on top of the garment and each colour must be “screened” individually.

PRO'S

- Cost effective for high volumes & larger image sizes.

- Typically durable for the rigours of daily wear and constant washing.

ADDITIONAL BENEFITS THROUGH TMA SUPPLY

- Repeat set up costs either minimal or not charged.

- On-premise equipment with orders supplied within days where required.

- Our team has over 20 years of experience & use the most current screen printing machines & inks.

CON'S

- Higher set up costs, especially for jobs requiring multiple coloured screen set ups.

- More costly for low quantity orders.

- Colour limitations & prints only as solid colours (no gradient colour option)

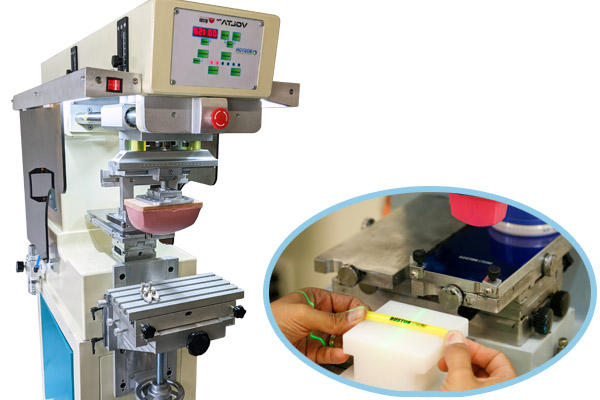

PAD PRINTING

Pad Printing involves printing a 2D image on a 3D object. It is also known as tompography and tampo printing, an indirect photogravure process. This means the pad (indirect offset/ gravure) in the printing machine uses heat to transfer the image from the flat printing plate to the object.

This process can print detailed and high-quality images on objects with uneven shapes and surfaces at a good speed. Consequently, it is an invaluable process in the medical, automotive, electrical, and several other industries.

PRO'S

- High quality prints onto 3D, curved surfaces.

- Compatible across different materials & surfaces.

- Cost effective print option.

ADDITIONAL BENEFITS THROUGH TMA SUPPLY

- Repeat set up costs either minimal or not charged.

- On-premise equipment with orders supplied within days where required.

- Our team has over 20 years of experience & use the most current tompography machines & inks.

CON'S

- Suitable only for smaller print areas.

- Can scratch or wear off with regular wear and tear on some items.

LASER ENGRAVING

Laser engraving is the practice of using lasers to engrave an object. The technique does not involve the use of inks, nor does it involve tool bits which contact the engraving surface and wear out, giving it an advantage over alternative engraving or marking technologies where inks or bit heads are replaced regularly. It also allows for a 2D image to be applied on a 3D object.

This process provides detailed and high-quality images on objects with uneven shapes and surfaces at a good speed. Consequently, it is an invaluable process in the medical, automotive, electrical, and several other industries.

PRO'S

- High precision images onto 3D, curved surfaces.

- Incredibly versatile across different materials & surfaces.

- Cost effective print option.

- Low set up costs.

ADDITIONAL BENEFITS THROUGH TMA SUPPLY

- Repeat set up costs either minimal or not charged.

- On-premise equipment with orders supplied within days where required.

- Our team has over 20 years of experience & use the most current tompography machines & inks.

CON'S

- No options for different colours.